The Nitto Group's manufacturing is based on the use of the Earth's limited natural resources, and we believe that the efficient use of resources is our corporate mission. In addition to reducing waste through waste management and efficient resource utilization at each business location, we will promote technological development for resource circulation, aiming to realize a recycling-oriented society.

Many of the Nitto Group's products use raw materials derived from fossil fuels. To enable our customers to use earth-friendly products, we are increasing the use of sustainable raw materials, such as recycled materials and biomass materials, for main and secondary materials, such as base films for tapes, adhesives, and packaging materials. Regarding organic solvents, we promote solvent recycling by reusing the solvents used in the manufacturing process. We will also respond to the increasing demand for technologies and products related to the recycling of resources and materials.

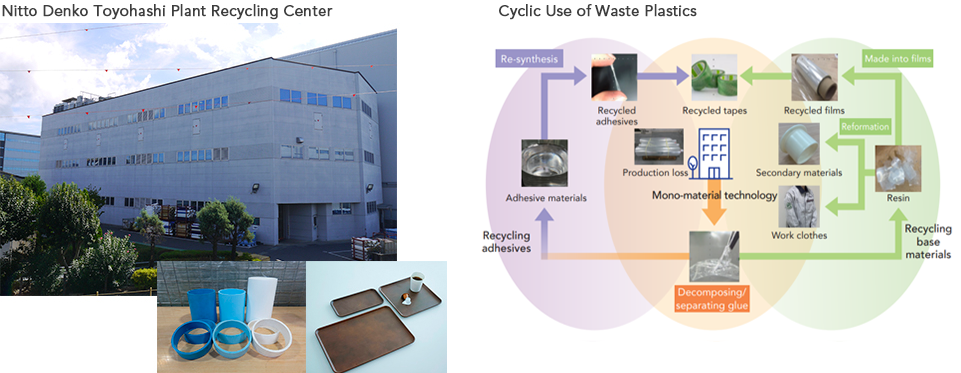

Approximately 50% of the waste generated by the Nitto Group is plastic products, a resource derived from petroleum, and as such, we are promoting activities aimed at increasing the waste plastic recycling ratio. To improve recycling rates, it is important to separate composite materials into single materials. For this reason, Nitto is developing plastic material recycling technology.

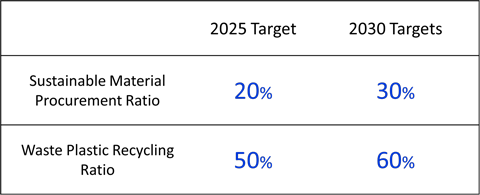

We have set environmental targets of achieving a 30% sustainable material procurement ratio and a 60% waste plastic recycling ratio by 2030, and are steadily progressing toward these targets.

Resource circulation target

|

In order to accelerate recycling, it is important to separate materials into mono-materials. The Nitto Group is working on developing technology to separate composite materials.

One example is the technology for separating the adhesive and base material in tape products. With this technology, we are taking on the challenge of separating and breaking down the glue applied to the base material, turning the adhesive back into adhesive raw material and the base material into resin raw material, thereby turning them into work clothes, auxiliary materials, and films. By establishing these mass production technologies, we aim to achieve our 2030 targets and contribute to a circular economy.

(Left: Tape core made from recycled plastic, Right: Tray made from recycled plastic for cafeteria) |

Since a large amount of GHG (CO2) is emitted during the combustion of solvent gases, we have installed solvent recovery equipment. Recovering solvents not only reduces GHG (CO2) emissions, but also leads to more efficient use of resources. We are developing processes that do not use organic solvents, and are promoting the recycling of used solvents that are collected after use.

Photo: Solvent recovery system at Nitto Belgium |