-Under the slogan “Place Safety Before Everything else”, The Nitto Group will work together to firmly establish a safe and healthy work place for all employees by observing company rules-

In order to realize this, we carry out the following safety principles:

This basic policy, which was approved by the Corporate Strategy Meeting, applies not only to all Nitto directors and employees but also to all those working within the Nitto Group (contractors or individuals under the company’s supervision). In order to make the above easily understood and well known, they have been incorporated into Nitto Group “Business Conduct Guidelines” to create a safe and healthy work environment for all Nitto employees.

Setting “safe manufacturing” as one of its material issues for sustainability (materiality), the Nitto Group has been strengthening its efforts towards occupational safety and health. In order to solve occupational safety and health issues, the Group is working to establish and promote short- to mid-term and long-term strategies by establishing a governance system where President-Director & CEO is appointed as the superintendent, and where the Corporate Strategy Meeting body plays the central role under the direction and supervision of the Board of Directors.

In addition, in order to enhance the effectiveness of our occupational safety and health initiatives, we have a department responsible for group-wide occupational safety and health, led by an executive officer in charge of promoting occupational health and safety-related issues.

The department responsible for group occupational safety and health narrows down the highest –priority issues from among those emerging from the safety and health activities of sites, business sectors, areas, and group companies across the globe and sets a policy of action. Based on this policy, the department is working on various activities for occupational safety and health in collaboration with sites, business sectors, areas, and group companies in Japan and abroad. To this end, discussions are held regularly for coordination between the department and individuals responsible for occupational safety and health at each business sector and area. On major issues, the executive officer responsible for occupational safety and health reports them to the management through Corporate Strategy Meetings and other means to take action group-wide.

With the aim of reducing all types of accidents and injuries to zero, the Nitto Group is currently committed to achieving zero critical or serious accidents, eliminating significant accidents including fatal ones. In order to achieve this goal, we monthly monitor and manage the number of critical and serious accidents as well as that of general accidents and evaluate our progress toward the goal. We also analyze the details of accidents that have occurred, and work on improvements to prevent recurrence. Improvement activities are not limited to the site where accidents occurred and are rolled out to other sites with similar processes and operations to prevent accidents or injuries throughout the entire group.

For the most recent accident data, please refer to the Sustainability Data Book

|

The Nitto Group is committed to reducing risks by ensuring the safety of machines, as Nitto operates many types of machines and equipment.

In order to reduce work-related accident risks, the Nitto Group employs its own unique approaches to risk assessment, addressing both machinery- and operational safety. Risk assessments are conducted as early as the planning stage of machinery and equipment, as part of our proactive safety initiatives. In FY2022 the objective of reducing all risks regarded as material issues was accomplished. For 2023, the company continued to focus its efforts on eliminating “A-rank risks,” which were identified as significant hazards. Moreover, the company has introduced and is globally rolling out chemical risk assessments to reduce accident risks in handling chemical substances.

As part of risk-reduction efforts, the Nitto Group is also pursuing the adoption of new technologies including AI. The newly developed “Mixing-Roll hazardous behavior/protective equipment use detection AI system” was certified as conforming to the “Safety 2.0 compliance registration system,” which is promoted by IGSAP* from the viewpoint of industrial accident prevention. We will continue to develop new safety technologies in the future.

The Nitto Group implements various activities to raise the safety awareness of its employees.

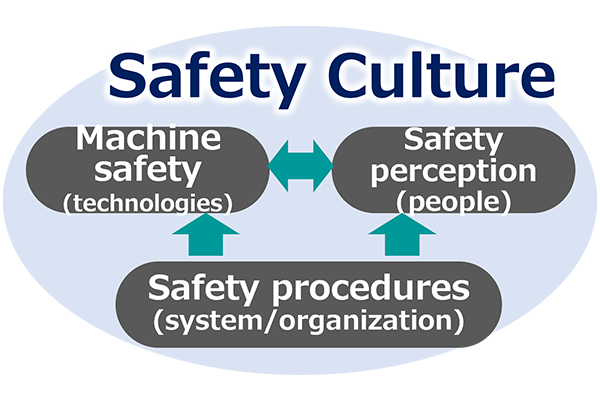

With the aim of cultivating a safety culture, we have developed our own unique system to assess the level of safety culture at each site, which is currently being rolled out globally. By visualizing the safety level at each site, we will identify issues and further improve our safety culture.

In order to enhance the value of safety practices, we annually hold a safety promotion conference by connecting each site online, where the President, all our executive officers and safety leaders from various global areas gather. By awarding excellent safety activities and sites with excellent safety performance, we are striving to further stimulate safety practices and motivate employees, and thereby promote individual growth on safety.

The Nitto Group has established mechanisms to ensure safety throughout the organization.

We have introduced the occupational safety and health management system (ISO 45001), etc. at each site for continuous improvement of occupational safety and health level.

Click here on the certification acquisition status: Link

At the Nitto Group, each site periodically self-checks the implementation status of Group-wide standardized safety activities. In addition, the department responsible for group-wide occupational safety and health participates in internal audits conducted by the Internal Audit Department to confirm compliance status with occupational health and safety-related laws and regulations as well as the implementation of safety activities.

The Nitto Group believes that knowledge of occupational safety and health is vital in preventing occupational accidents. For this reason, we ensure that all employees receive the training and qualifications required by law. We also provide various types of internal and external training related to occupational safety and health, including general training, position-based training, and specialized training.

The Nitto Group provides globally standardized safety and health training to new employees, where they learn the basics of safety and health, as well as Nitto’s approach to safety. Follow-up training is also provided several years later as a review.

In order to prevent occupational accidents similar to those that have actually occurred within the Group, we share detailed information of these accidents with all managers. In line with this, hazard prediction training based on such actual accidents is provided to employees.

As part of our efforts to develop safety personnel, we encourage all managers to acquire the Safety Officer Certification*. By being certified for safety management with the possession and understanding of safety-related knowledge, we are aiming to integrate top-down and bottom-up safety knowledge, thereby improving the effectiveness of safety activities, which in turn will lead to not only safety improvement but also to corporate growth and increased corporate value.

In the event of an accident, in accordance with Nitto Group’s regulations, a report is promptly made to relevant departments, and its causes are thoroughly investigated and recurrence prevention measures are implemented by the site where the accident occurred.

To prevent occupational accidents of a similar nature, their details are shared within the Group.

Furthermore, in the event of a critical or serious accident, a report thereof is made to the Corporate Strategy Meeting in order to promote Group-wide efforts to prevent recurrence.

In the event of a major incident or serious accident, there is a system in place to immediately report it to top management. Upon receipt of a report, if top management determines it necessary, an emergency HQ is immediately set up and the entire Group provides support to the affected Group companies and sites.

By placing ESG at the core of its management, the Nitto Group implements all its activities based on its Basic Policy on Sustainability. It is promoting ESG activities with the aim to transform “future financial-target” activities into “financial-target” activities, and into corporate value, based on the idea that ESG activities are not costs but a business (investment). On top of that, by formulating a Basic Policy on Human Resource Management that positions “human resources as its most important asset,” the Group is working to secure and develop human resources and create a healthy workplace environment.

The same applies to the “health” of our employees. Based on the idea that “human resources are our most important asset” and drawing up the Good Health Declaration, the entire Group is engaged in the promotion of employees’ health. We believe that investing in the health of our employees will be conducive to organizational revitalization, including increased employee vitality and productivity, which in turn will lead to improved business performance and organizational value.

For any inquiries about Nitto.

Business Hours(Japan time)

9:00-17:30(Except for Sat, Sun, and Holidays)