Nitto Denko's Thin-film Metal Base Board CISFLEX™ play an important role in transferring data to and from recording media and maintaining fly height at a minute 10nm above the recording media thanks to their delicate spring characteristics.

|

CISFLEX™ |

In 1988, a certain young engineer at Nitto Denko (known in those days as Nitto Electric Industrial Co., Ltd.) was sent to Chiba University. Although this was at the request of the engineer, who sensed his own lack of ability, it was also because the company had a strong desire to develop necessary new technology. During the three years of his doctoral course he developed new photosensitive polyimide technology using completely new materials and photosensitive functions.

Polyimide is widely used in electronics, as it is outstanding in terms of heat-resistance, insulation, flatness and α-ray shielding characteristics. By adding a photobase generator, which is a photosensitizing agent, a base was produced when exposed to light, which was designed to promote the dissolution of the polyimide. This in turn opened up many new possibilities.

In 1991, this young engineer, who had returned from Chiba University to Nitto Denko, was carrying out further research regarding the use of this new photosensitive polyimide technology in various products. As we have already seen at the end of Chapter 1, this technology used positive material design where the polyimide that was exposed to light dissolved. It was, however, proving difficult to develop. As a base is produced when the photobase generator is exposed to light, a complex is formed between a base and the polyimide precursor, which is polyamic acid. If this material is then developed in an alkaline solution the polyimide dissolves, leaving only the areas that were not exposed to light on the substrate to produce a “positive” image (please see the right hand column of Figure 1).

However, with the materials that were used at that time, there was no adequate difference in dissolving speed between exposed areas and unexposed areas, meaning that the pattern resulting from this phenomenon could hardly be said to be ideal. Therefore, it was not possible to use this technology to form the fine patterns required on protective films for electronic parts, which was one of the areas in which it was hoped the technology could be commercialized. Experiments were repeatedly carried out in order to realize the difference in dissolving speed that is necessary to produce the fine patterns required.

The answer presented itself on March 16, 1992. The engineer was once again performing experiments late into the night, still wondering why it was impossible to achieve clean positive patterns. “I think I’ll go home,” he said to himself and left an exposed sample in the dryer while he went and smoked a cigarette. On returning, while cleaning up he took the sample from the dryer and developed it in the normal way. Much to his surprise it was a negative (the area that was exposed to light was not dissolved) and not a positive image.

Although this principle would become clearer in the days that lay ahead, by leaving the sample in the dryer for an hour rather than the usual ten minutes, an unexpected chemical side reaction occurred in the photosensitive material after the photoreaction had already taken place (the amine compounds produced through the photoreaction of the photobase generator) and the substance produced through that reaction was a thermally stable insoluble substance. Furthermore, it was theoretically proven that as the amine compounds produced by exposure to light acted as an imidizing catalyst, only the polyamide acid that had been exposed to light could not be dissolved by the alkaline developing solution. Of course, the area that had not been exposed to light was dissolved by the alkaline developing solution on account of the carbonic acid residue of the polyamic acid (please see the left hand column of Figure 1).

In this way the “negative” photosensitive polyimide was achieved.

Figure 1. The principle of negative and positive photosensitive polyimide processing. |

Photosensitive polyimide makes it possible to form patterns using a shorter process.

|

Figure 2. Polyimide pattern processing Photosensitive polyimide makes it possible to form patterns using a shorter process. |

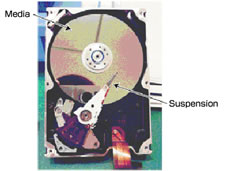

Figure 3. The inside of a typical HDD |

At the time, the role of HDD suspensions was merely to hold the magnetic head and data was transferred by separate wires. However, as HDDs became larger, faster and more compact, the limitations of manual assembly using wires quickly became apparent. There was the possibility that forming circuits directly on the suspension holding the magnetic heads and using this photosensitive polyimide as an insulation layer would solve this problem (see Figures 2 and 3). |

Although photosensitive polyimide itself was, of course, essential, without the use of other technology the commercialization of this product would still have been impossible. In order to successfully commercialize this product, other technology, such as sputtering and coating, was required, and in order to combine them with elemental technology all group companies had to work together. At the start of the project, engineers from every department within the company got together to ascertain what technology would be necessary for commercialization. Although many difficulties were encountered and the project took one year longer than expected, commercialization was achieved in 1998. Over the course of the following three years, the product took the market by storm, resulting in a 100% transition from conventional-type wire suspensions to circuit-type suspensions. During that time we enjoyed the enthusiastic support of many material, equipment and part suppliers and were able to spin off the business as an independent operation.

Taking a concept from technology through to a new product is the task of researchers and in reality is a process that is fraught with risks. However, the engineer who was responsible for overseeing this concept from the development of material technology to commercialization maintains that he did not particular feel any uncertainty throughout the entire process.

“I was confident in the technology and persistent, but whenever I had any trouble other people were quick to help me.”

With regard to the continuous hard work and late nights he said, “It was fun because it was something that I wanted to do.”

Although customers were at times quite critical, he turned his disappointment into positive energy and kept on going. As a result, he still has contact with many of these people over 10 years later.

If one develops a technology in which they are confident and they persistently work away at thing, then this should lead in a positive direction.

The fact that he had the enthusiastic support of management and was able to provide a place with a conducive environment in which young researchers could work to fulfill their potential were also probably contributing factors.

Since that time, research regarding CISFLEX™ involving many people has continued on a daily basis and it is expected that in the future, with the addition of new technology, that the product will continue to evolve to meet the changing needs of the market.

Business Hours(Taiwan time)

8:30-17:30 (Except for Sat, Sun, and Holidays)